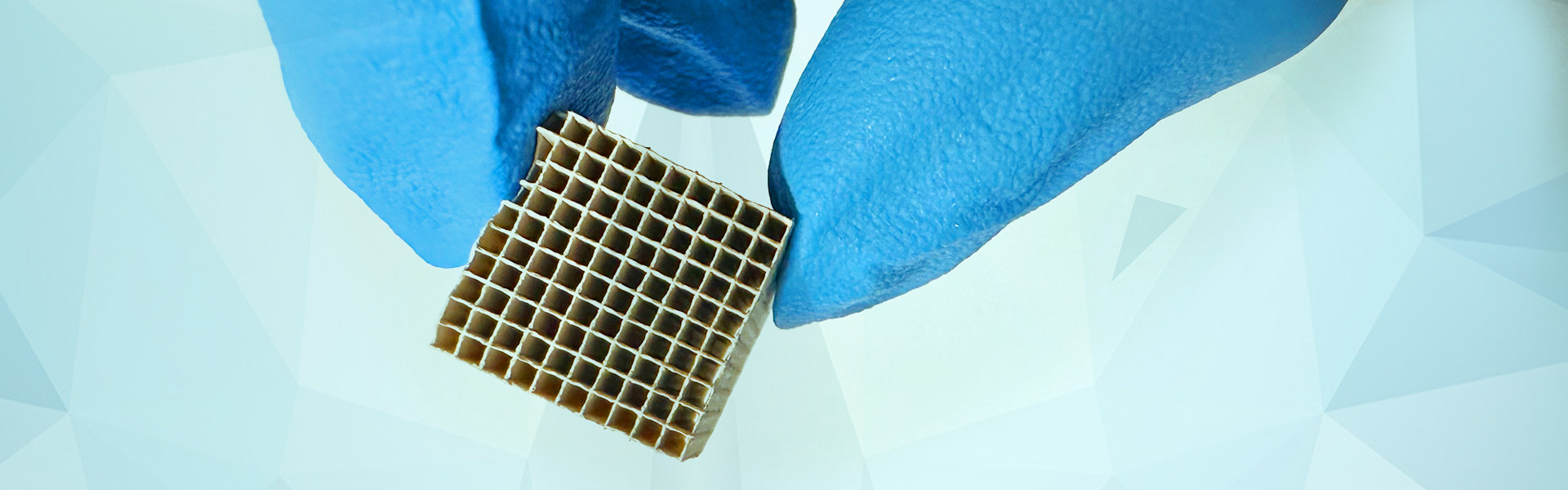

Scalable and cost-effective synthesis and assembly of technologically important nanostructures in three-dimensional (3D) substrates hold keys to bridge the demonstrated nanotechnologies in academia with industrially relevant scalable manufacturing. In this work, using ZnO nanorod arrays as an example, a hydrothermal-based continuous flow synthesis (CFS) method is successfully used to integrate the nano-arrays in multi-channeled monolithic cordierite. Compared to the batch process, CFS enhances the average growth rate of nano-arrays by 125%, with the average length increasing from 2 μm to 4.5 μm within the same growth time of 4 hours. The precursor utilization efficiency of CFS is enhanced by 9 times compared to that of batch process by preserving the majority of precursors in recyclable solution. Computational fluid dynamic simulation suggests a steady-state solution flow and mass transport inside the channels of honeycomb substrates, giving rise to steady and consecutive growth of ZnO nano-arrays with an average length of 10 μm in 12 h. The monolithic ZnO nano-array-integrated cordierite obtained through CFS shows enhanced low-temperature (200 °C) desulfurization capacity and recyclability in comparison to ZnO powder wash-coated cordierite. This can be attributed to exposed ZnO {10[1 with combining macron]0} planes, better dispersion and stronger interactions between sorbent and reactant in the ZnO nanorod arrays, as well as the sintering-resistance of nano-array configurations during sulfidation–regeneration cycles. With the demonstrated scalable synthesis and desulfurization performance of ZnO nano-arrays, a promising, industrially relevant integration strategy is provided to fabricate metal oxide nano-array-based monolithic devices for various environmental and energy applications.

RESULTS

RESULTS

- HOME /

- PUBLICATIONS /

- RESULTS /

- 正文

39.Scalable Continuous Flow Synthesis of ZnO Nanorod Arrays in 3-D Ceramic Honeycomb Substrate for Low Temperature Desulfurization

发布时间:2023-06-02 浏览次数: